CNC Machining In Metro Detroit

Detroit's Go To CNC Machining Shop, Located In Troy

About Manik Machining

At Manik Machining, we are a premier CNC machining provider based in Troy, MI. Rooted in Detroit’s industrial hub, we deliver high-quality machined parts with precision and speed. Our mission is to exceed expectations through advanced technology and skilled craftsmanship. We serve clients from startups to established firms, offering tailored solutions from prototype to production. With a focus on clear communication and reliability, we treat every project with care. Choose Manik Machining for expertise, innovation, and results that drive your success in manufacturing.

A veteran owned company

Our Services

Prototype Machining

Prototyping is where innovation begins, and at Manik Machining, we excel in bringing concepts to tangible forms quickly and accurately. Our prototype machining services allow you to test designs, iterate rapidly, and refine products before committing to full production. Using our advanced CNC machines, we can produce small batches or single pieces with high precision, reducing lead times and costs associated with traditional methods.

We work closely with engineers and designers to understand your requirements, offering insights to optimize designs for manufacturability. Whether it's a complex geometric shape or a functional prototype, our team ensures every detail is captured. This service is ideal for industries requiring fast turnaround, such as product development and R&D, helping you stay ahead in competitive markets.

Production Machining

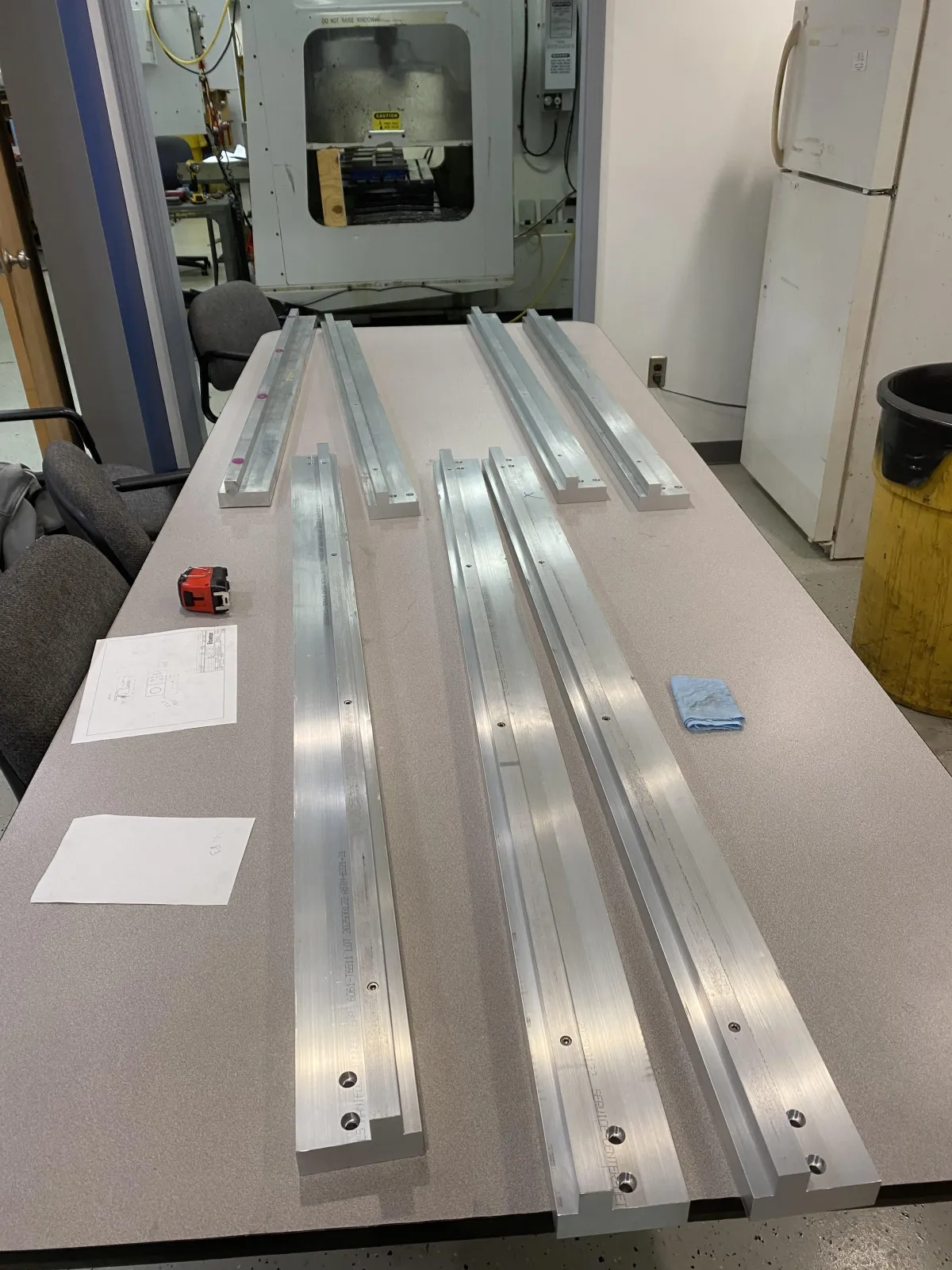

When it's time to scale up, our production machining services deliver consistent, high-quality parts in larger quantities. We handle runs from medium to high volume, maintaining tight tolerances and superior surface finishes throughout. Our efficient processes minimize waste and maximize output, making us a reliable partner for ongoing manufacturing needs.

Equipped with robust machinery, we can machine a variety of materials, ensuring durability and performance in the final product. Our production capabilities include multi-axis machining for intricate parts, allowing us to tackle challenging projects with ease. By streamlining operations and implementing rigorous quality checks, we ensure every batch meets your standards, reducing downtime and enhancing your supply chain efficiency.

In addition to core machining, we offer value-added services like assembly, finishing, and packaging to provide a complete solution. This integrated approach saves you time and resources, allowing you to focus on your core business while we handle the manufacturing intricacies.

Need to discuss your businesses individual requirements?

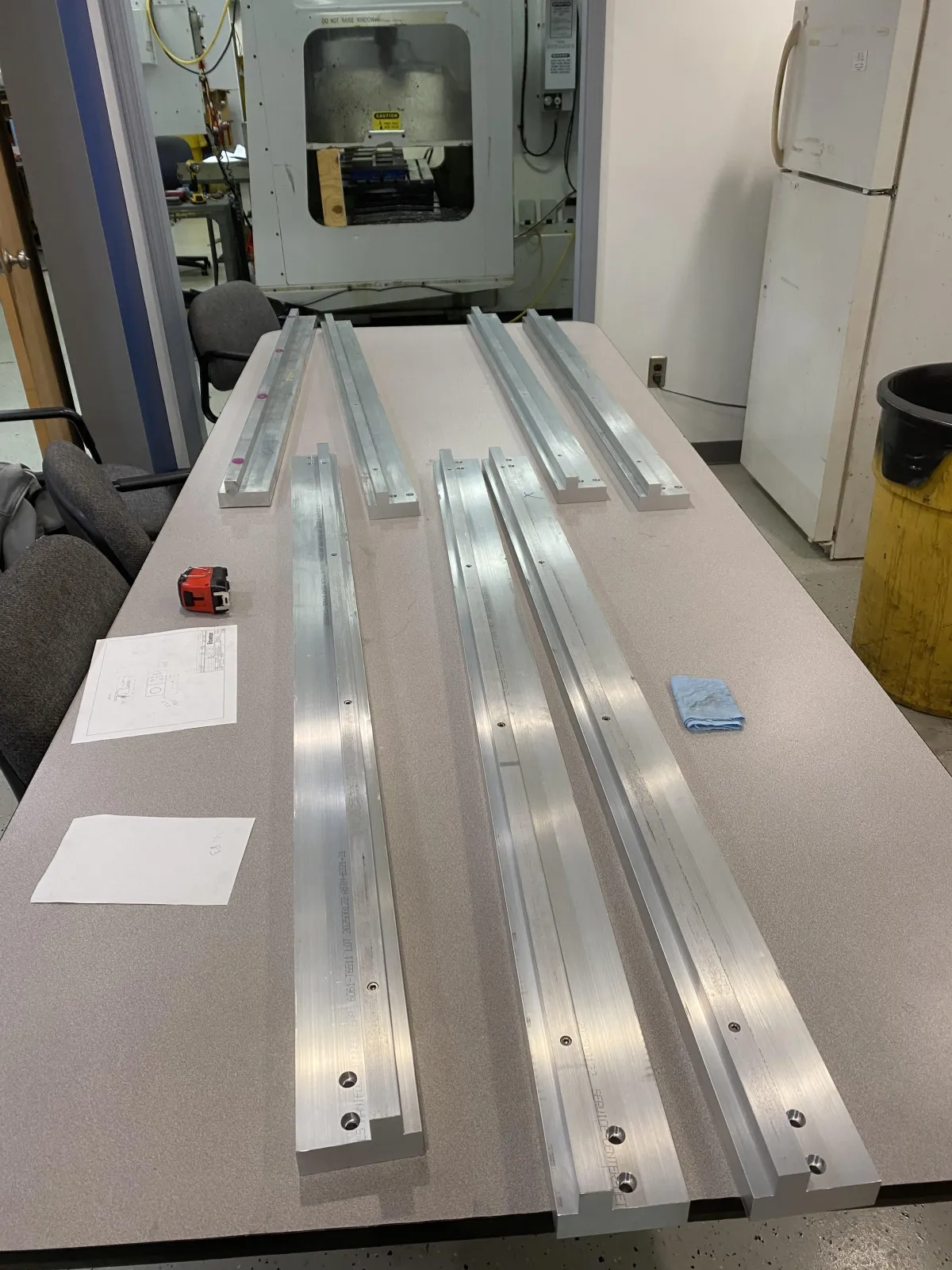

Machinery

We utilize high-performance CNC machines to achieve unparalleled precision and efficiency. Our lineup includes the HAAS VF-4, a versatile vertical machining center known for its reliability and speed in handling complex milling operations. This machine excels in producing detailed parts with excellent repeatability.

Complementing this is the OKUMA MX-45VAE, a robust CNC mill that offers advanced features like high-speed spindle and rigid construction for superior accuracy. It's ideal for both prototyping and production, capable of machining tough materials with ease. Together, these machines allow us to process parts up to certain sizes—contact us for specific dimensions—and maintain tolerances as tight as industry standards demand.

Our facility is maintained to the highest cleanliness and safety standards, ensuring optimal performance of our equipment and the safety of our team.

Software

To enhance our machining capabilities, we employ sophisticated CAD-CAM software. This technology bridges the gap between design and production, allowing for seamless translation of digital models into physical parts.

Our software enables precise toolpath generation, simulation of machining processes, and optimization to reduce cycle times and material usage.

By integrating CAD-CAM, we can import files from various formats, make necessary adjustments, and program machines efficiently.

This not only speeds up production but also minimizes errors, ensuring your parts are machined correctly the first time. Our team is proficient in using this software to handle intricate designs, making us capable of tackling projects that require high levels of customization.

Enquiries

Want to know more about how we could help your business?

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

FOLLOW US

COMPANY

CUSTOMER CARE

Copyright 2025. Manik Machining. All Rights Reserved.